Cable Enhancement

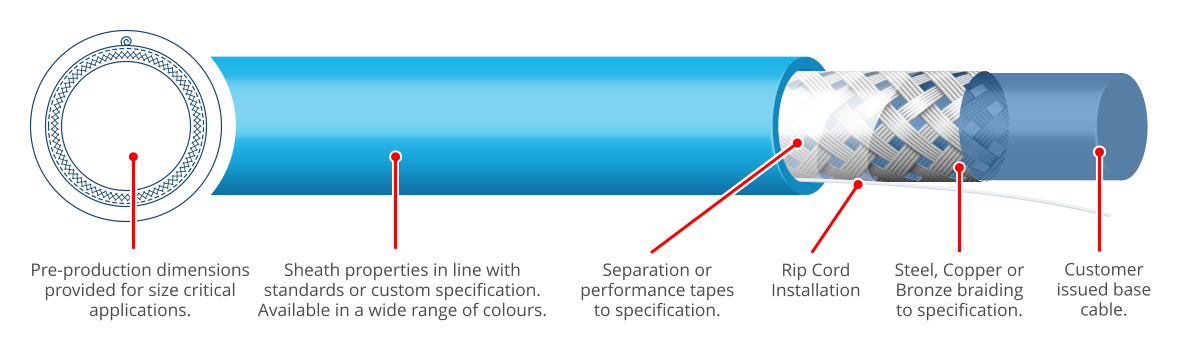

Braiding

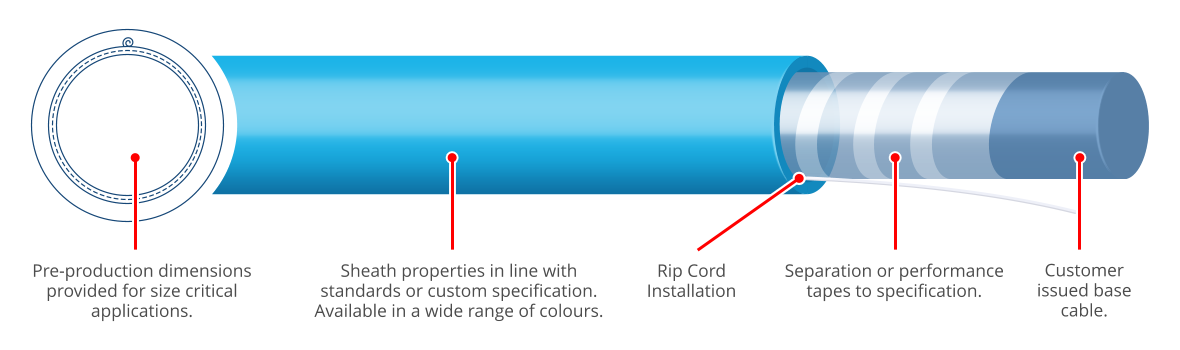

Layup & Tapes

Armouring

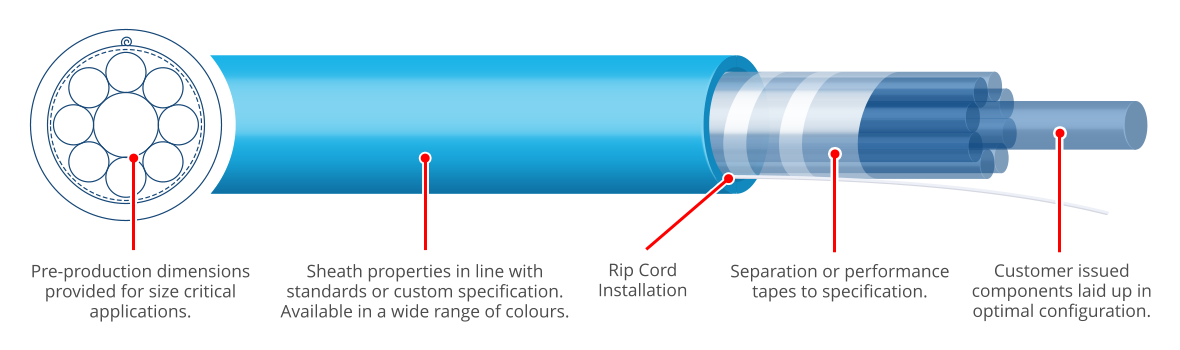

Composites

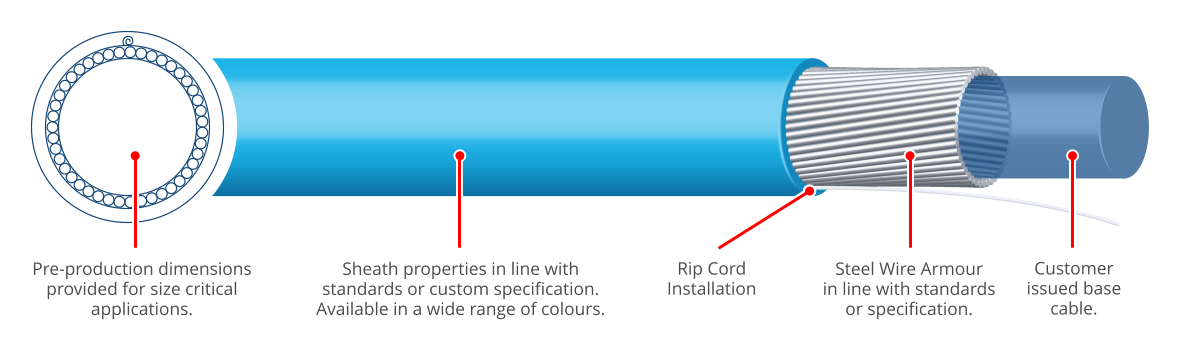

Armouring & Sheathing

We can enhance your existing inventory to include the mechanical protection offered by steel wire armour before completing the cable with an extruded jacket using materials chosen to suit your application or specification. These might include low and high temperature performance, flexibility, water resistance, oil and chemical resistance, toxicity, fire reaction and smoke emissions.

We offer SWA (Steel Wire Armour) in both stainless and the more commonly used galvanised steel. We can armour cables with coverage to suit, typically using wires with nominal diameters of 0.87mm, 1.21mm, 1.54mm and 1.94mm.

Our materials meet various International, British, European and Industry Standards & Specifications and are sourced from reputable manufacturers. We take great pride in our polymer sciences to ensure the right choice of material and processing techniques for the application.

For this process we accept free issue cables from 5mm to approximately 32mm in diameter.

Braiding & Sheathing

We can respecify free issue stock with wire braids to provide mechanical protection or electrical shielding before being finished with an extruded jacket material to suit the intended application or environment. Our braiding is offered in various wire metals including tinned or plain annealed copper, galvanised or stainless steel and phosphor bronze.

Our typical braid wire diameters are 0.20mm and 0.30mm but other sizes can be offered. We can also process fibre braiding such as Vectran, subject to viability.

Typical sheathing materials include Low Smoke Zero Halogen, Polyethylene, PVC and highly flexible and resistant materials such as PUR or TPV. We can sheath cables to your precise colour specification and print the jacket with custom text.

For this process we can accept free issue cables from just 2mm upwards.

Over Sheathing

Our manufacturing facility operates several extrusion lines producing core insulation and jacket sheathing in a comprehensive range of materials selected for their performance characteristics. These might include low and high temperature performance, flexibility, water resistance, oil and chemical resistance, toxicity, fire reaction and smoke emissions.

Our materials meet various International, British, European and Industry Standards & Specifications and are sourced from reputable manufacturers. We take great pride in our polymer sciences to ensure the right choice of material and processing techniques for the application.

Our typical insulation and sheathing grades include:

- LDPE (Low Density Polyethylene)

- MDPE (Medium Density Polyethylene)

- HDPE (High Density Polyethylene)

- XLPE (Crosslinked Polyethylene)

- Zyrad™ Modified XLPO (Electron Beam Irradiation Cross Linked Polymer)

- PVC (Polyvinyl Chloride)

- LSZH (Low Smoke Zero Halogen)

- XL-LSZH (Crosslinked Low Smoke Zero Halogen)

- Extruded EPR (Ethylene Propylene Rubber)

- Extruded TPV (Thermoplastic Vulcanisate)

- PUR (Polyurethane)

- TPE (Thermoplastic Elastomer)

- Other material grades can be offered depending on viability.